- Tablet Press Machine

- Single Tablet Press Machine

- Rotary Tablet Press Machine

- High Speed Tablet Press Machine

- THP Flower Basket Tablet Press Machine

- Double Layer Press Machine

- Three Layers Tablet Press Machine

- Hydraulic Press Machine

- GD Isostatic Ball Press Machine

- Powder Mixing Machine

- CH Series Trough Mixer

- V Series High Efficient Mixer

- SBH Three-Dimensional Swing Mixer

- Mixer Reactor

- Pharmaceutical Pulverizer

- Ice Crusher Machine

- SF Series Pulverizer

- SFB Series Pulverizer

- Powder Sieve Machine

- XZS Full Stainless Steel Sieve Machine

- SY Series Vibrating Screen Machine

- Granulator Machine

- ZL Series Rotary Granulator

- YK Granulation Machine

- GL Series Dry Granulator

- High-Efficient Wet Mixing Granulator

- FL Series Fluid Bed Granulator

- Dryer Machine

- RXH Warm Air Cycle Oven

- LPG High Speed Centrifugal Spray Dry

- GFG High Efficiency Boiling Dryer

- FG Fluid Bed Dryer

- Coating Machine

- BY Sugar Coating Machine

- BYS Series Coating Machine

- Pharmaceutical Packaging Machinery

- Dzb-600 Tablet Packing Machine

- Sachet Packing Machine

- Blister Packing Machine

- Capsule Filling Machine

- NJP-200C /400C/800C Automatic Capsule Filling Machine

- NJP-1200C Fully Automatic Capsule Filling

- DTJ-V Semi Automatic Capsule Filling Machine

- Auxiliary Machine

- Pneumatic Vacuum Loading Machine

- Powder Removal Machine

- YPJ-C Capsule Polisher

- XCJ-36 Suction machine

- Wire Drawing Die

- The Nature Diamond Finished Drawing Die

- Natrual Diamond Finshed Tin Plated Drawing Die

- Imported Polycrytal Finished Drawing Die

- Advanced Polycrytal Finished Drawing Die

- Natural Dlamond Semi-Finished Drawing Die

- Natural Diamond semi-finished Tin plated drawing die

- Advanced Polycrytal Semi-Finished Drawing Die

- Shaped Wire Drawing Die

- Enamelled Die

Wire Drawing Die

- Nature Diamond Finished Drawing DieThe nature diamond drawing die is stable quality ,high precision, good wear ability, comes from the strict selection to high quality nature diamond semi-finished drawing die, according to user of different drawing materials, design and manufacture of wire drawing die shape, choose the best compression angle, and first class technology...

- Natrual Diamond Finshed Tin Plated Drawing DieThe Natural diamond tin plated drawing die with die with the technology of Ti alloy powder metallurgy, the proportion lighter than tin solution....

- Imported Polycrytal Finished Drawing DieOur imported polycrystalline drawing die core from American GE and Japan Sumitomo source, its quality is extremely stable..

- Advanced Polycrytal Finished Drawing DieOur advanced polycrystalline die range 0.10-8.00mm, this series of drawing die has two types: The soft wire die and hard wire die. The soft wire die is good for the drawing of high quality copper wire, the hard wire is better for the drawing of high hardness nickel chromium wire, stainless steel wire , tungsten and molybdenum wires. Advanced polycrystalline drawing dies has the advantages of high-quality die and reasonable price especially on user performance....

- Natural Diamond Semi-Finished Drawing DieThe diamond semi-finished wire has superior quality and performance. Each diamond accepts by strict inspection so as to ensure the diamond internal defects and clear outline. Then each diamond after carefully grinding surface, to ensure maximum wear ability . Each diamonds with proper installment, to ensure the parallelism and the central position of diamond , the hole shape and size are according to the needs of any change...

- Natural Diamond semi-finished Tin plated drawing dieThe Diamond semi-finished Tin plated drawing die has high technical .Die case(coat) is titanium alloy material. it is not stick tin, not easy to break, in the hot state of powder has good thermal stability .each tin plated semi finished diamond has to undergo a rigorous inspection to ensure all diamond are no internal defects and clear outline. Great polish for each diamond in purpose to ensure maximum wear ability. Die hole size and angel can be changed as practical....

- Advanced Polycrytal Semi-Finished Drawing DieAdvanced polycrystalline semi-finished wire drawing die adopted to best cobalt based polycrystalline diamond with stable performance. Meanwhile the sintering equipments as automatically far infrared temperature, strict control of temperature and pressure in order to guarantee its excellent performance. Each die polycrystalline are properly installed, to be ensuring the parallelism and center of the polycrystalline and elegant appearance. Die hole size and angle can be determined according to customer requirements ....

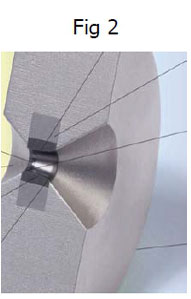

- shaped wire drawing dieOur company has hard metal shaped drawing die. Such as square shape, rectangle shape, oval shape ,triangular shape ,half round, six angle …… we also could produce the drawing die according to customer requirements. We can design and manufacture polycrystalline shaped drawing die. The lifetime is hundreds times higher than hard metal carbide wire drawing die. The perfect uniform of the products from special –shape die, greatly improve customer competitive in their market. ....

- Enamelled DieOur company enameled dies for enameled wire, the natural diamond, ruby, hard alloy have been embedded horizontally and vertically, it can automatically center, magnet wire more accurate, more uniform insulation layer, greatly improve the magnet wire insulation performance , the customer can choose standard horizontal, vertical enameling dies, the enameling dies can also required according to the customer requests. Its geometric structure makes easy to lead the wire. The anti seeping design guarantees the evenness ...

Description

Our company engaging in Wire drawing dies production. My mainly products are Tungsten carbide drawing die, Natural diamond drawing die, tin coated, imported advanced polycrystalline drawing die, extrusion die and various special-shape die. At the same time, we also could offer the semi-finished products to meet the customer requirements. My company annual output of 200000 finished wire drawing die being in basis on domestic and overseas.

Company Feature

We buy the equipment from overseas to improve the production process control and product performance.

With rich experience in technology and production team, with advanced production management experience and testing equipment to keep the die in high quality

The brief instruction Wire Drawing die.products overview

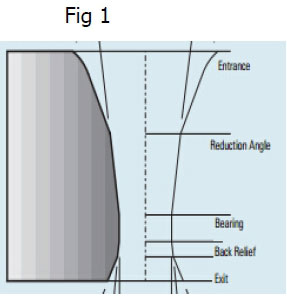

The Instruction of the wire Mold Entrance-Reduction angle –Bearing-Back relief-exit The Production diameter Range: 0.010—8.000mm

English

English Español

Español Русский

Русский Français

Français