- Tablet Press Machine

- Single Tablet Press Machine

- Rotary Tablet Press Machine

- ZP-5/7/9/5A/7A/9A/5B/7B/9B

- ZP-13A/15A/17A/19A/21A

- ZP-13B/15B/17B/19B/21B

- ZP-15/17/19

- ZP 27 Punching Automatic Rotator Tablet Press Machine

- ZP 33 Rotary Tablet Press Machine

- ZPW-17/19D

- ZP-35D/37D/41D

- ZPW-21A/21B

- ZPW-29/31

- ZP 25B Rotary Tablet Press Machine

- ZPW 23 Soup Cube Tablet Press Machine

- ZP 23 Rotary Tablet Press Machine

- High Speed Tablet Press Machine

- THP Flower Basket Tablet Press Machine

- Double Layer Press Machine

- Three Layers Tablet Press Machine

- Hydraulic Press Machine

- GD Isostatic Ball Press Machine

- Powder Mixing Machine

- CH Series Trough Mixer

- V Series High Efficient Mixer

- SBH Three-Dimensional Swing Mixer

- Mixer Reactor

- Pharmaceutical Pulverizer

- Ice Crusher Machine

- SF Series Pulverizer

- SFB Series Pulverizer

- Powder Sieve Machine

- XZS Full Stainless Steel Sieve Machine

- SY Series Vibrating Screen Machine

- Granulator Machine

- ZL Series Rotary Granulator

- YK Granulation Machine

- GL Series Dry Granulator

- High-Efficient Wet Mixing Granulator

- FL Series Fluid Bed Granulator

- Dryer Machine

- RXH Warm Air Cycle Oven

- LPG High Speed Centrifugal Spray Dry

- GFG High Efficiency Boiling Dryer

- FG Fluid Bed Dryer

- Coating Machine

- BY Sugar Coating Machine

- BYS Series Coating Machine

- Pharmaceutical Packaging Machinery

- Dzb-600 Tablet Packing Machine

- Sachet Packing Machine

- Blister Packing Machine

- Capsule Filling Machine

- NJP-200C /400C/800C Automatic Capsule Filling Machine

- NJP-1200C Fully Automatic Capsule Filling

- DTJ-V Semi Automatic Capsule Filling Machine

- Auxiliary Machine

- Pneumatic Vacuum Loading Machine

- Powder Removal Machine

- YPJ-C Capsule Polisher

- XCJ-36 Suction machine

- Wire Drawing Die

- The Nature Diamond Finished Drawing Die

- Natrual Diamond Finshed Tin Plated Drawing Die

- Imported Polycrytal Finished Drawing Die

- Advanced Polycrytal Finished Drawing Die

- Natural Dlamond Semi-Finished Drawing Die

- Natural Diamond semi-finished Tin plated drawing die

- Advanced Polycrytal Semi-Finished Drawing Die

- Shaped Wire Drawing Die

- Enamelled Die

ZP13A/15A/17A/19A/21A Rotary Tablet Press Machine

Main Application

ZP13A/15A/17A/19A/21A rotary tablet press machine is a multi-functional rotary tablet press. It has a wide range of applications. This rotary tableting machine can be used for making watercolor tablet, disinfection tablet, camphor tablet, and so on. It can not only be applied in pharmaceutical, medicine, pill and foodstuff industries but also used in the chemical, ceramic, electronic and battery industries.

Features

1. The motor of this multi-functional rotary tablet press is 5.5 kW to 7.5 kW. It has bigger pressure.

2. This rotary tableting machine has the variable-frequency drive system. The speed is adjustable.

3. It could press round tablets or other special tablets in oval shape, square shape, capsule shape, heart shape, five star shape, etc.

4. The multi-functional rotary tablet press could press two layers tablets (If the customer requires.).

5. This rotary tableting machine is enclosed with organic glass and stainless steel.

Technique Parameters

| Number of Punching Dies | 13 | 15 | 17 | 19 | 21 |

| Max. Pressure (KN) | 150 | 150 | 120 | 120 | 80 |

| Max. Tablet Diameter (mm) | 50 | 45 | 40 | 30 | 30 |

| Max. Filling Depth (mm) | 18-25 | 18-25 | 18-25 | 18-25 | 18 |

| Max. Thickness (mm) | 8-15 | 8-15 | 8-15 | 8-15 | 9 |

| Capacity (pcs/h) | 7800-19500 | 9000-23000 | 10200-25500 | 11400-28500 | 45000 |

| Power (kW) | 7.5 kW, 6 Grade | 7.5 kW, 6 Grade | 7.5 kW, 6 Grade | 7.5 kW, 6 Grade | 3 kW |

| Outside Size (mm) | 900 × 800 × 1640 | 900 × 800 × 1640 | 900 × 800 × 1640 | 900 × 800 × 1640 | 900 × 800 × 1640 |

| Weight (kg) | 1500 | 1500 | 1500 | 1500 | 1500 |

Delivery

The delivery time of this rotary tableting machine is 30 working days from the receipt of down payment and samples of products to be operated on the machine. (The actual delivery time depends on your order.)

Service

1. Guarantee

The guarantee period for this multi-functional rotary tablet press is thirteen months from shipment date. During this period, we will provide free maintenance and free spare parts that caused by the machine’s quality, but customers must pay the express fee. Parts damaged because of mishandling and consumable parts are not covered by any warranty.

2. Installation and Adjusting

We send the technician to customers’ factories for installing and adjusting this rotary tableting machine and training the workers if customers invite. The installing and adjusting cost is 80 USD per day. Customers should pay round tickets and accommodation expenses for our technicians.

1. Force Feeder

2. Sheath

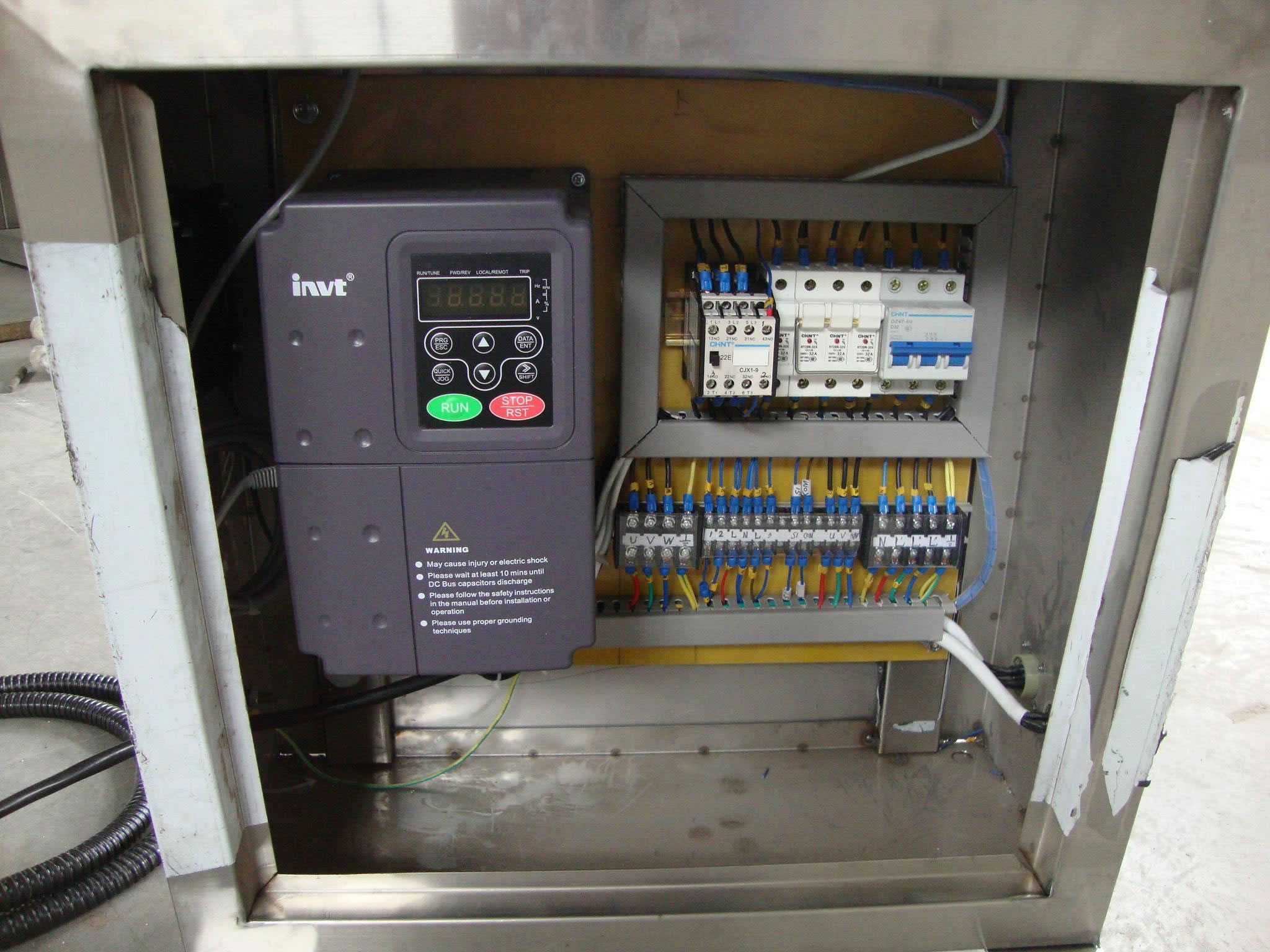

3. Electric Control Box

4. Main Parts for the Machine

- ZP13B/15B/17B/19B/21B Rotary Tablet Press MachineZP13B/15B/17B/19B/21B rotary tablet compression machine is a multifunctional tablet press. It can press oval shape, oblong shape, round shape and other special shape tablets if customers change different dies and punches. It can press disinfection tablet, camphor ball, pill, chemical tablet and the pill for animals, and so on. The rotary tablet compression machine has a wide scope of application. This tablet...

English

English Español

Español Русский

Русский Français

Français